A cylindrical die is used in rotary die cutting, a specialized form of die cutting, to create shapes from materials. It revolves continuously and features blades that carve off the required shape all the way around the cylinder. Because it rotates while cutting out numerous identical forms, this is highly effective. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

Rotary die cutting is the process of choice for producing thin film and pressure sensitive adhesive tape die cuts in high volume. CFS utilizes the flexibility provided by our machinery and tooling to produce in-line laminating, kiss cutting, scoring, split lining, sheeting, kitting, and perforating. Quantities from prototypes and short runs to large production volumes. Large library of materials...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

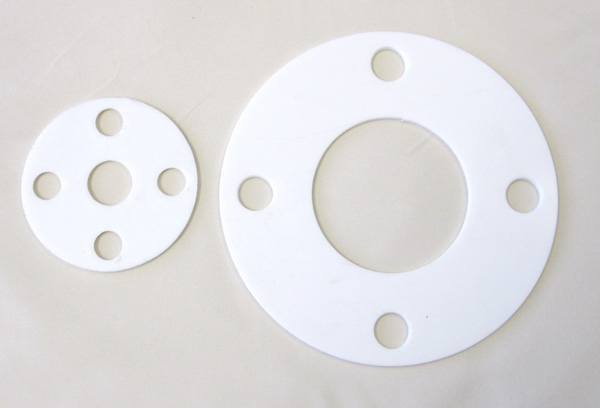

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Rotary Die Cutting Companies

What is Rotary Die Cutting?

All that needs to be done is to flip a switch and place a sizable sheet of material underneath the rotor. This is perfect for use in fields like engineering where it's critical that plastic and metal sheets have the exact same dimensions for a piece of machinery to function.

Additionally, it is necessary for printing bandages, creating adhesive sheets that fit on identical-sized objects, and even producing military equipment in the exact specifications that the military requires.

Rotary Die Cutting Process

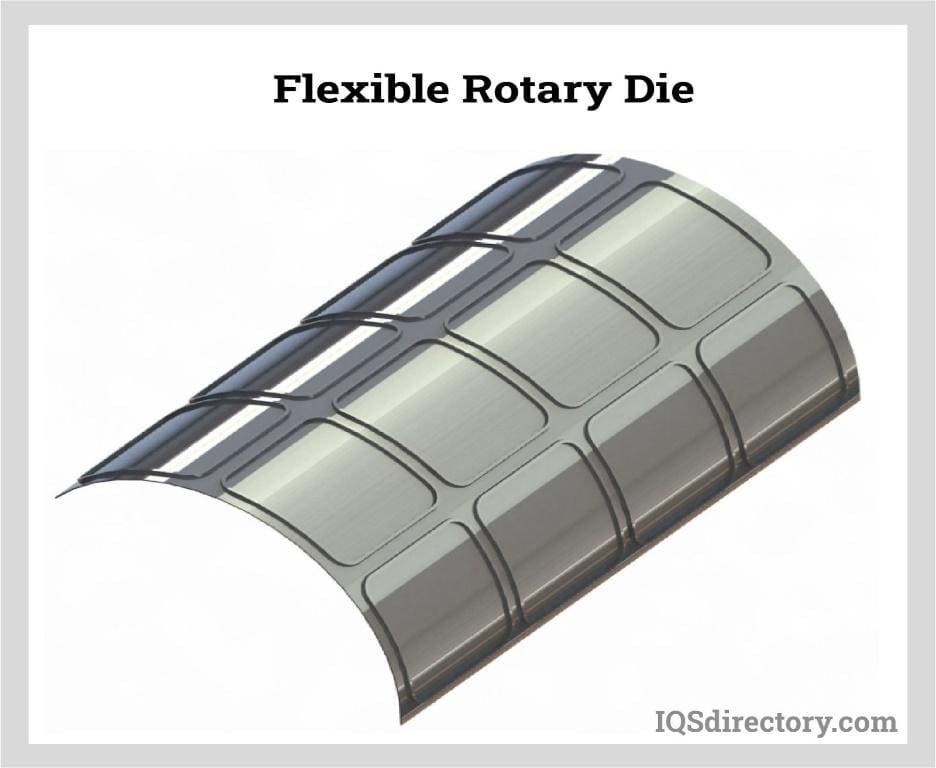

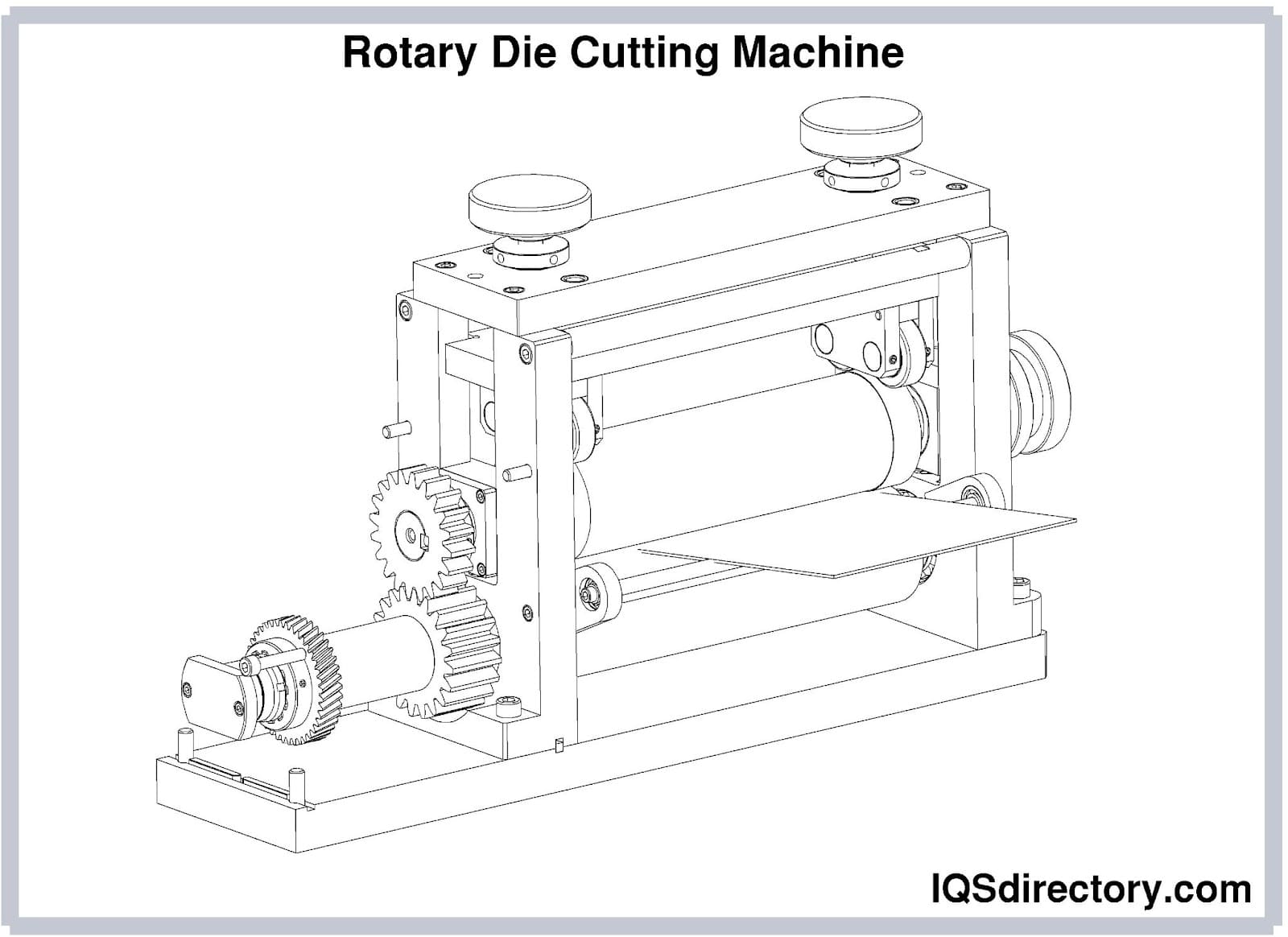

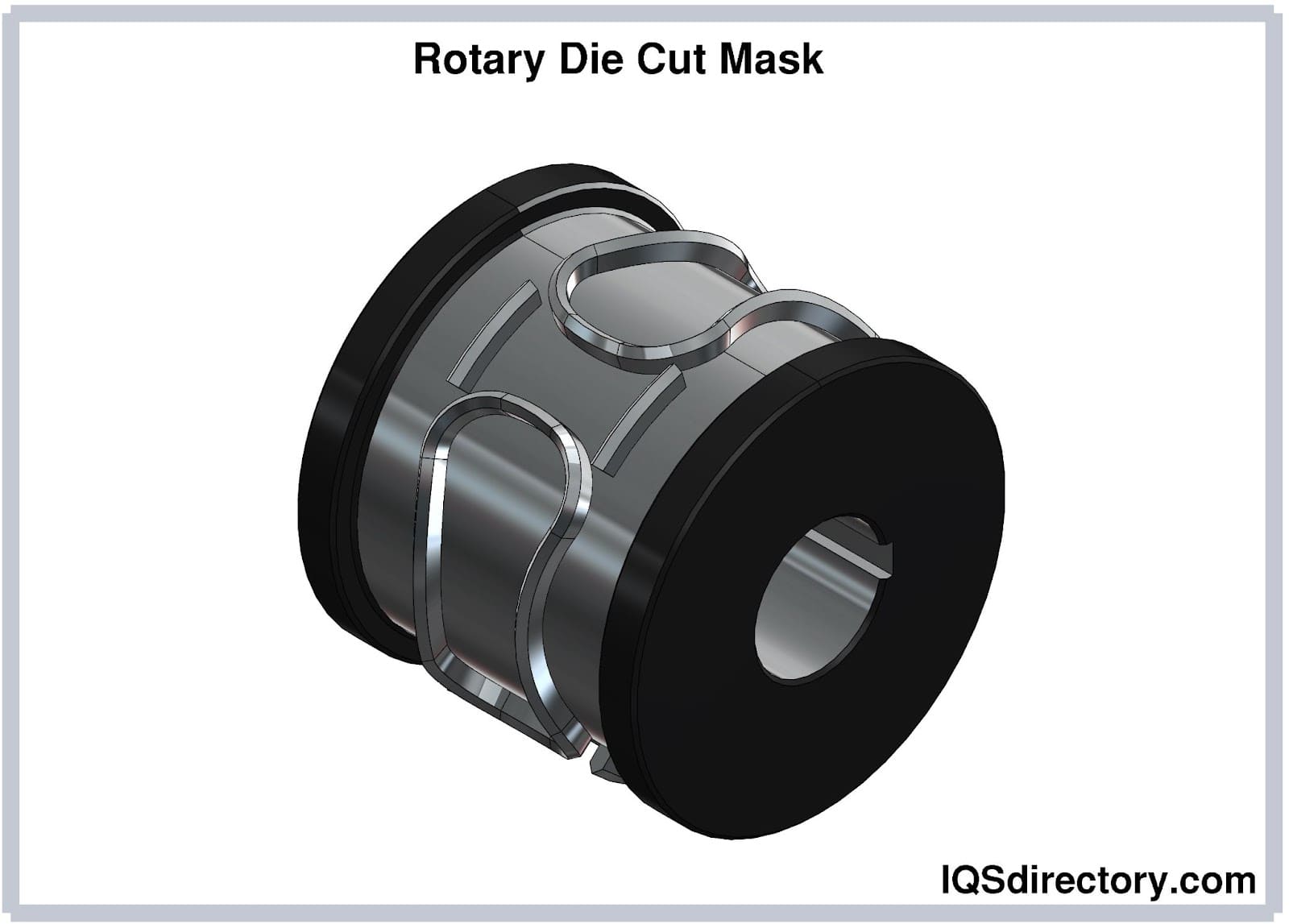

Using a rotary press, the material is unrolled and fed through two rollers to begin the rotary die cutting procedure. The hard cylindrical anvil is one of the rollers, and the other is a cylindrical die, also known as a rotating die.

After being engraved, sharpened, and heat treated, the angled blades are machined into the die. A solid engraved die or an adjustable die may be utilized in this procedure. A solid engraved die is frequently machined from a solid steel bar, giving tighter tolerances. An adjustable die's blades are easily replaceable if wear or the need to cut a new material arises.

Blades are employed to drive the material against the anvil's surface, regardless of the type of die being used. Many webs can be processed and merged by the rotary die cutting machine in a single pass because materials are frequently chopped into webs.

Materials may be conveyed through the machine by a release liner, rolled onto a new core, or sheeted into pads. Metal-to-metal die cutting or kiss cutting, also known as butt-cutting, are the two different ways to cut through the materials and their release liner.

Cutting completely through the material and its release liner is required for metal-to-metal die cutting. When kiss cutting, the material is just cut through to the releasing lining. The same piece of equipment may carry out several cuts and laminations thanks to rotary die cutting's capacity to input and register material at fast speeds.

More complex components can be added during the stacking process, such as island placement—placing an item inside a web—in-line packing and adding peel tabs.

Applications of Rotary Die Cutting

Medical tools and wound care

Numerous issues in the medical industry can be resolved by rotary die cutting for adhesive. One of the most popular tools in the medical field is medical adhesive tape since it can be used to address a wide variety of problems, many of which are very common.

In addition to being pressure-sensitive, these adhesive tapes are breathable, making them gentle on the user's skin. According to this, any additional solvent or heat solution is not needed. Furthermore, various materials, including waterproof adhesive and robust cloth tape, can be cut by rotary die-cutting machines into adhesive medical tape.

These tapes benefit from a die cut because it guarantees that every component is the right size and shape to stick directly to a patient's skin, healing the wound with the least discomfort possible.

When sticky tape clings too firmly to the skin, preventing it from breathing, this is a typical issue in the medical industry. This problem can be resolved by using a rotary die cut to create the ideal materials because the medical tape that comes off the machine is made of any breathable material you choose.

Thermal masking

Cold weather causes a range of issues in numerous businesses. When temperatures drop, machinery in factories or work zones stops operating. Not only that, but inadequate insulation can make working conditions for workers uncomfortable or even dangerous. The correct adhesive can adhere thermal masking tape to virtually any surface, providing insulation.

Military use

Soldiers can stay warm by using adhesive thermal tape on their boots, helmets, and other military gear. To prevent their surfaces from being scratched in the line of fire, thermal tape can also coat weapons like tanks and assault rifles. Additionally, these adhesives can increase the equipment's resistance to severe weather.

Choosing the Right Rotary Die Cutting Company

To ensure the most positive outcome when selecting a rotary die cutting business, it is important to compare several companies using our directory of rotary die cutting businesses. Each rotary die cutting company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each rotary die cutting business website using our patented website previewer for an understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple rotary die cutting businesses with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

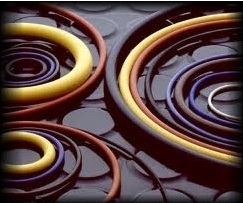

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services