Shapes made out of foam sheets by a die cutter are known as die-cut foam items. Die cutters are stamping or rolling devices that cut flat sheets into custom-designed forms. Metal, plastic, wood, rubber, and other materials can all be cut into desired forms using die cutters. Several different things are made with die cut foam. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS is an ISO 9001:2015 manufacturer of custom die cuts. We supply laser, steel rule, automated flatbed and standard rotary die cutting, dieless knife cutting services. Precision die cutting achieves tolerances as tight as +/- 0.002". Services include kitting, sheeting, perforating, kiss cutting, tabs and split liners. Printing available on die cuts in performed in our ISO Class 7 Clean Room. We...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

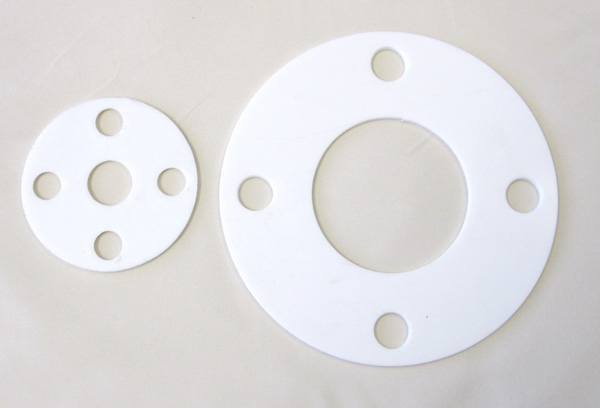

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Die Cut Foam Companies

Foam Die Cutting Process

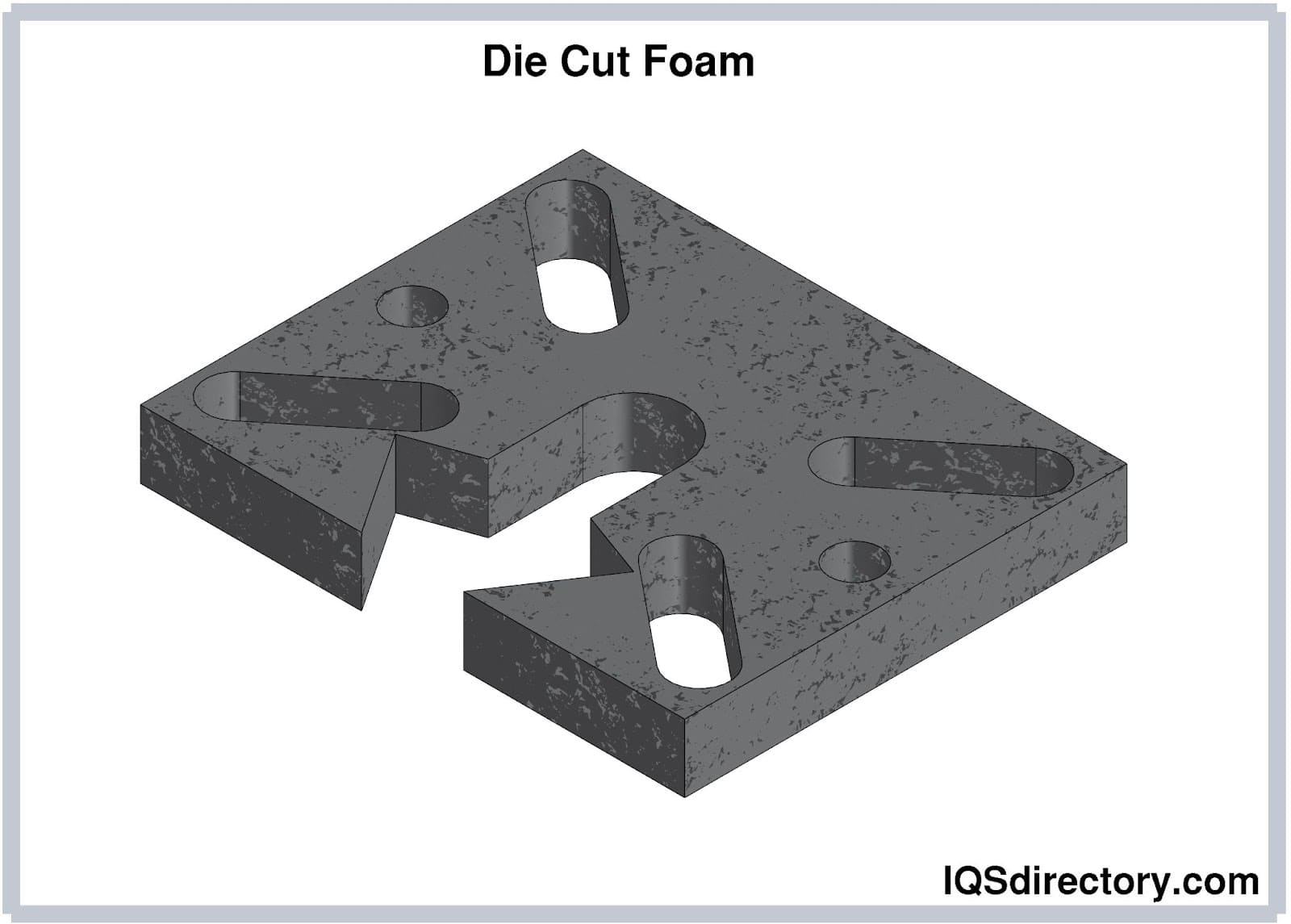

Die cut machines are used to produce every die cut foam product. Every die cut machine can be specifically set up to produce a particular form. Thin blades, referred to as dies, are used in die-cutting to carve forms out of various materials.

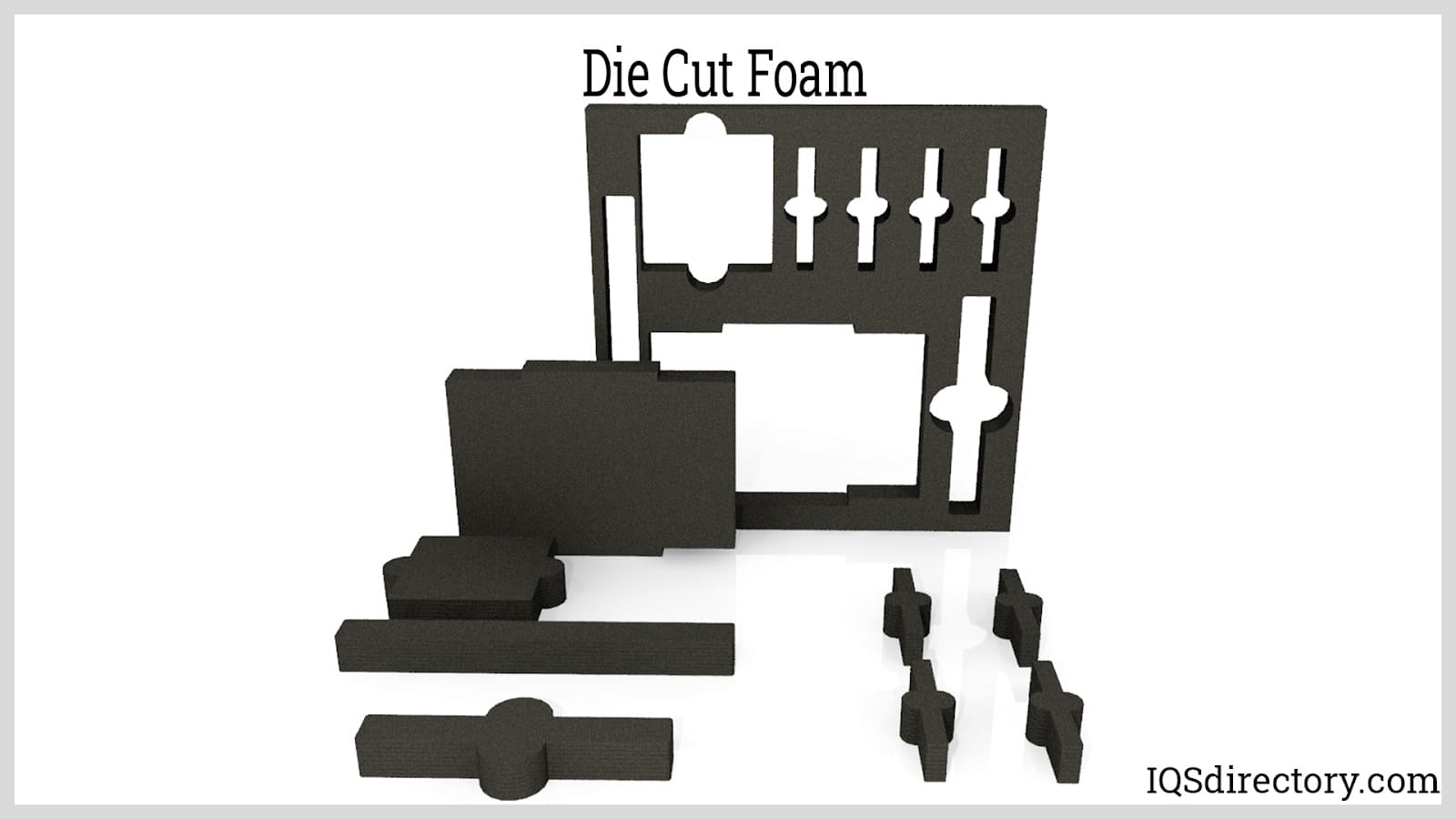

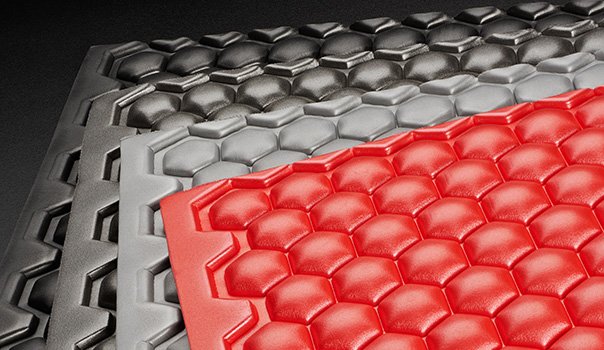

Cutting foam into unique shapes and sizes with die cutting is very effective and affordable. Moreover, it is compatible with practically all foam materials. Plastic, paper, felt, and other materials can also be made using this approach.

According to the product's electronic drawing, a steel die mold must be constructed before the die-cutting procedure. Once the die mold is created, die-cutting equipment can quickly create the necessary foam forms and sizes. The foam can be cut in the following ways:

Steel Rule Cutting

When using steel rule die cutting, there will be three crucial components. They are flat die moldboards, rubber ejection layers, and cutting blades made of metal. A steel rule die cutter can efficiently stamp out material thanks to the coordinated action of the three pieces. Steel rule die cutting is a relatively common method for creating foam. It works well for cutting thick foam sheets and small orders using affordable tooling.

Kiss Cutting

When foam materials are cut with a kiss, finished foam portions are left on a removable layer, typically a paper liner or film. The final foam components remain on the detachable layer for ease of use. Kiss cutting is appropriate for creating thin foam materials because it is a shadow cut. It is typically used to produce custom foam pads, gaskets, and industrial insulation layers.

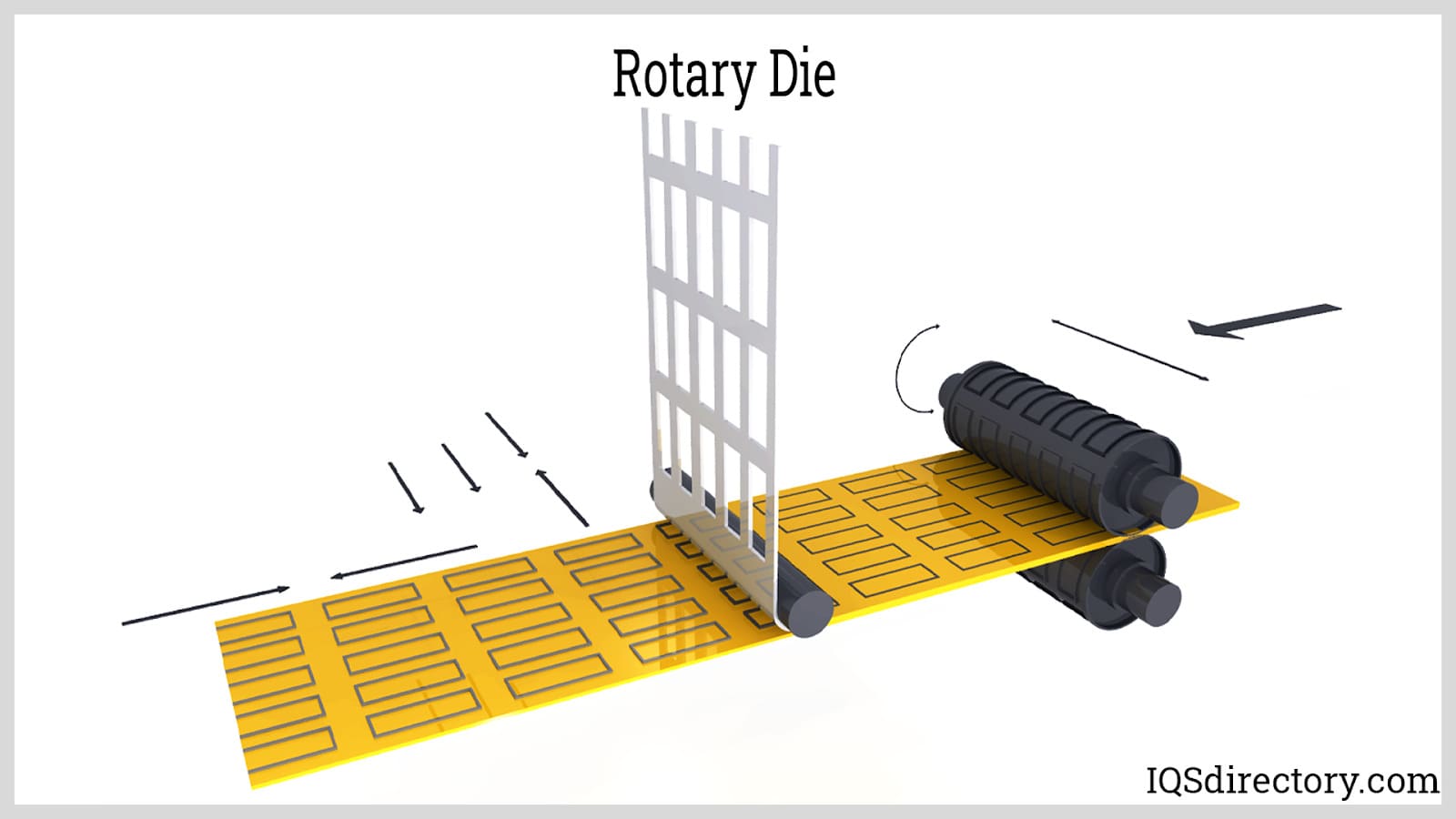

Rotary Die Cutting

Due to its high-speed productivity, rotary die cutting is frequently used to fabricate large quantities of foam parts. It is a relatively straightforward operation that resembles the rolling in place of a die through which flat foam material is fed. The part is pushed out in the proper shape when the cutting blade edge pinches the foam material. Making custom foam parts with rotary die cutting is another extremely accurate fabrication technique that is highly recommended for use with extremely thin foam materials like PVC foam, EPDM foam, and cross-linked polyethylene foam.

Manual Die Cutting

Die-cutting equipment in its most basic configuration resembles a mangle in many ways. A simple sandwich is made of two plates, and the die is inserted with the sharp edge facing the material. The pressure is then delivered throughout the entire die by winding the handle and cutting through the foam as it passes through.

Advantages of Die Cut Foam

- Die cutting is a highly effective method for producing different custom foam shapes and sizes.

- It is simple to work with every foam substance, including EVA foam, PE foam, and foam rubber.

- Production tooling costs are low.

- Die cutting is suitable for orders of both small and big volumes.

- Smaller and more regularly clicking devices are known as clickers.

- Although they cut more slowly, hydraulic presses cover a larger surface area.

- Cylindrical dies are used in rotary die cutting machines to enable the cutting and rapid expulsion of pieces.

Applications of Die Cut Foam

Die cut foam provides stress and vibration absorption when used in packaging, inserts, insulation, and cushioning. Die cut foam can be used in various products, including gaskets, seals, cushion pads, insulators, vibration mounts, sound dampening items, and more.

Die cut foam is particularly well-liked for use as permanent packaging and padding. In addition, specially shaped die cut foam products are used to secure many pricey, portable electronics or other sensitive equipment in their cases when not in use or when traveling. For instance, professionally crafted, impact-absorbent die cut cushions can shield camera lenses from damage.

Die cut foam is frequently used in recording studios and radio stations as an acoustically absorbent material. Additionally, die cut foam is frequently used to create novelty items like promotional items for sports teams.

Choosing the Right Die Cut Foam Company

To ensure you have the most positive experience when selecting a die cut foam business, it is important to compare several die cut foam companies using our directory of die cut foam companies. Each die cut foam business has a company profile page highlighting their areas of experience and capabilities, along with a contact form to directly contact the business for more information or request a quote. Review each die cut foam company using our patented website previewer for an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

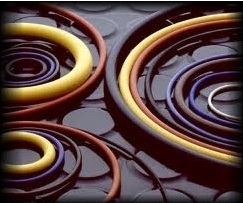

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services