When die-cutting plastic, the finished shaped components are cut from flat plastic sheets using a bespoke die made in the desired shape. Die cutting is typically less expensive and faster than other ways to cut plastic. Read More…

We know that high tech products require die cut parts that are created with precision and care. We have the highest quality standards in the die cutting industry because we know that with die cutting accuracy is so important. After we cut the prototype for your product and after receiving your approval we pledge that your orders will be shipped within ten business days or less.

CFS is an ISO 9001:2015 manufacturer of custom die cuts. We supply laser, steel rule, automated flatbed and standard rotary die cutting, dieless knife cutting services. Precision die cutting achieves tolerances as tight as +/- 0.002". Services include kitting, sheeting, perforating, kiss cutting, tabs and split liners. Printing available on die cuts in performed in our ISO Class 7 Clean Room. We...

When it comes to die cutting, we are the experts! We are a Grand Rapids, Michigan based company but we offer our services to all across the United States. It is our goal to bring exceptional die cutting services to all of our clients while also providing customer service that will keep you coming back to fulfill all of your die cutting needs. Our staff has the experience you can count on to...

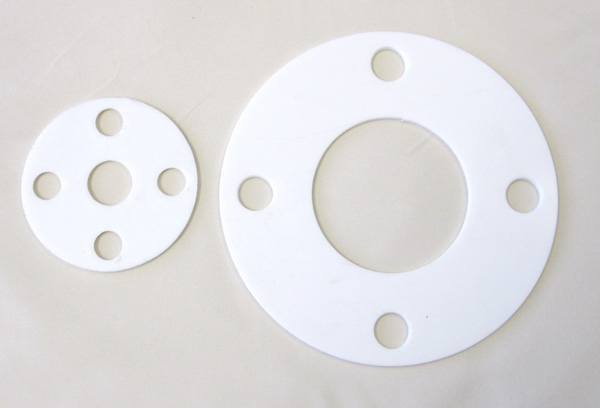

Gardico has been providing superior products and workmanship to industrial customers since 1977. Our die cutting capabilities satisfy needs for standard and custom gaskets, pads, insulators and decorative pieces in quantities from 5 or 10 to tens of thousands.

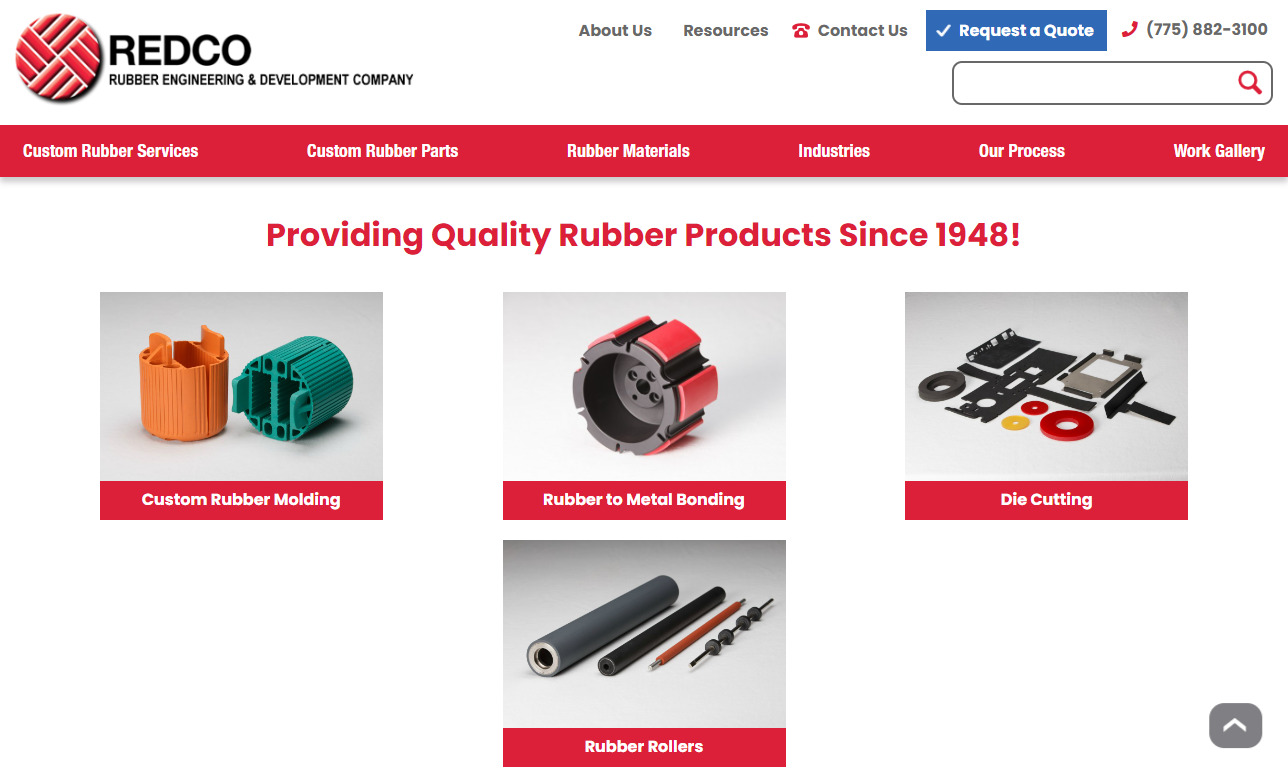

REDCO offers complete die cutting services to produce custom die cut gaskets and other custom die cuts that perfectly match our customers’ specifications. All of our steel rule dies are laser cut to guarantee quality and accuracy of the finished product. We have over 70 years of experience in die cutting non-metallic and metal parts. We strive to provide the best possible prices, the...

More Plastic Die Cutting Companies

What is Plastic Die Cutting?

Plastic die cutting is when a flat plastic sheet is pushed against a die-formed cutting edge to create a plastic piece that resembles the shape of the die with which it was cut. Although plastic shapes can also be cut with lasers or other specialized equipment and still be considered die-cut parts, a die in the context of plastic die cutting can be a particularly formed metal blade or group of blades.

All kinds of forms can be created using die cutting and various plastic materials. For example, die cutters can be used to create custom handles for thin plastic bags. Thin hard plastic sheets can be die-cut into a variety of forms. Die cutting is a simple process that can create miniature electronics faceplates and keyboard covers.

Also, die cutting is frequently used to produce keycards, employee name tags, and other small plastic cards. Plastic bags make up the majority of die-cut plastic products, despite the fact that a wide variety of plastic materials are candidates for the die-cut process.

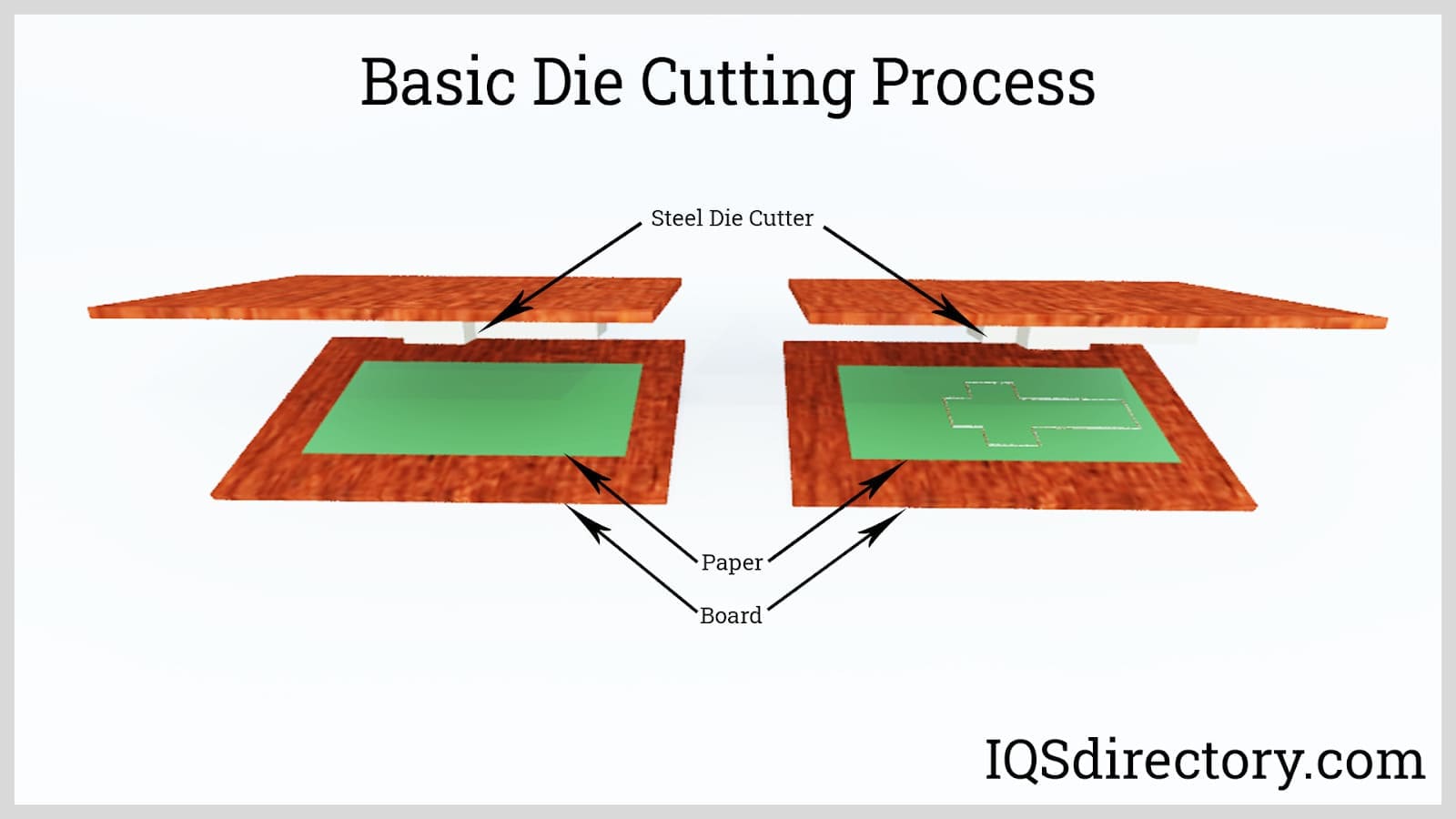

Die Cutting Process

The die-cutting procedure comprises picking the material and the appropriate equipment for the job, depending on the equipment utilized. A die may be required for techniques that don't employ lasers or rotary tools for cutting. Steel rule, rotary, and laser are the three principal die-cutting techniques. Every procedure has benefits and drawbacks, and not every job will benefit from using the same die-cutting technique.

Die-cutting techniques include:

Metal rule

The process of cutting steel rules, also known as flatbed cutting, begins with creating a special die. This manufacturing technique is perfect for high-volume projects that significantly rely on a precise shape because the die needs to be made first. Next, a turning instrument called a rotary die is used to cut or perforate a sheet of material.

Laser die

The final type of die cutting, also known as digital cutting, produces the forms digitally rather than using existing tools or dies. This method of cutting creates pieces with high tolerances because a laser can cut more accurately than a conventional tool.

Advantages of Plastic Die Cutting

- Die cutting is a cost-effective manufacturing solution, especially when produced in large quantities. Costs for increasing the order size change depending on the material used once manufacturers produce the necessary die.

- Customizability: Die cutting is not only inexpensive but also enables customized cuts. Any required shape can be produced using laser and steel rule die cutting.

- Flexibility: This method can cut various materials, including metals and wood. Die cutting is a versatile manufacturing method since it may be used for many tasks.

Disadvantages of Plastic Die Cutting

- Using a die cutter incorrectly could cause the material to be scored rather than cut through. This problem might be resolved by trying to run the project through the machine one more time. The second cut, however, might not line up with the first if the material moved between the first and second passes, leading to a cutout that is not round.

- The rotary cutters and steel rule dies are both extremely sharp. Physical harm could come from improperly handling them.

Applications of Plastic Die Cutting

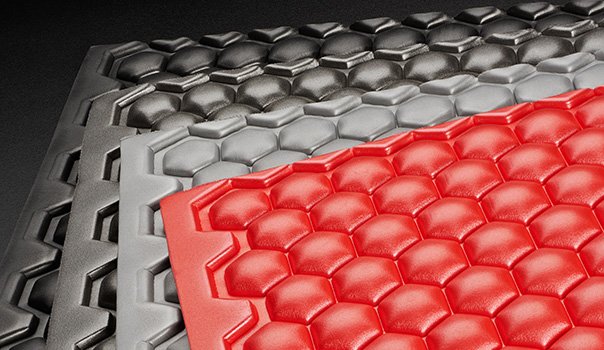

Applications requiring fluid resistance and heat sealing can use plastic die cutting. Plastic die cutting has advantages over conventional cutting techniques. High-speed, extremely accurate, and dependable plastic die-cutting machines are available.

When choosing a plastic die-cutting machine, it's important to consider its throat, stroke, operating force, open height, maximum sheet width, and maximum sheet length. Numerous thermoplastic materials, such as polyethylene, polycarbonate, polypropylene, styrene, PVC, PETG, Teflon, and polyurethane, can be cut using plastic dies.

Acrylics and other less robust plastic materials may not cut well even if they can be die cut. Die cutting is not limited to processing plastic. Die cutters can work with many materials, including wood, rubber, fabrics, and metal.

Companies that provide plastic die-cutting services occasionally also provide die-cutting of other materials. Every die-cutting operation is unique; some smaller operations only provide custom die-cutting in modest volumes, while larger companies typically provide stock die-cut products in substantial quantities.

Choosing the Proper Plastic Die Cutting Company

To ensure you have the most constructive outcome when selecting a plastic die cutting company, it is important to compare several businesses using our directory of plastic die cutting companies. Each plastic die cutting company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each plastic die cutting business website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

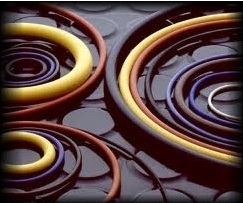

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services